How An Aircraft Actuator Can Improve The Efficiency

- - Category: Industrial

- - 22 Nov, 2022

- - Views: 329

- Save

By improving the efficiency with an aircraft actuator, it will help to improve the overall performance of the plane.

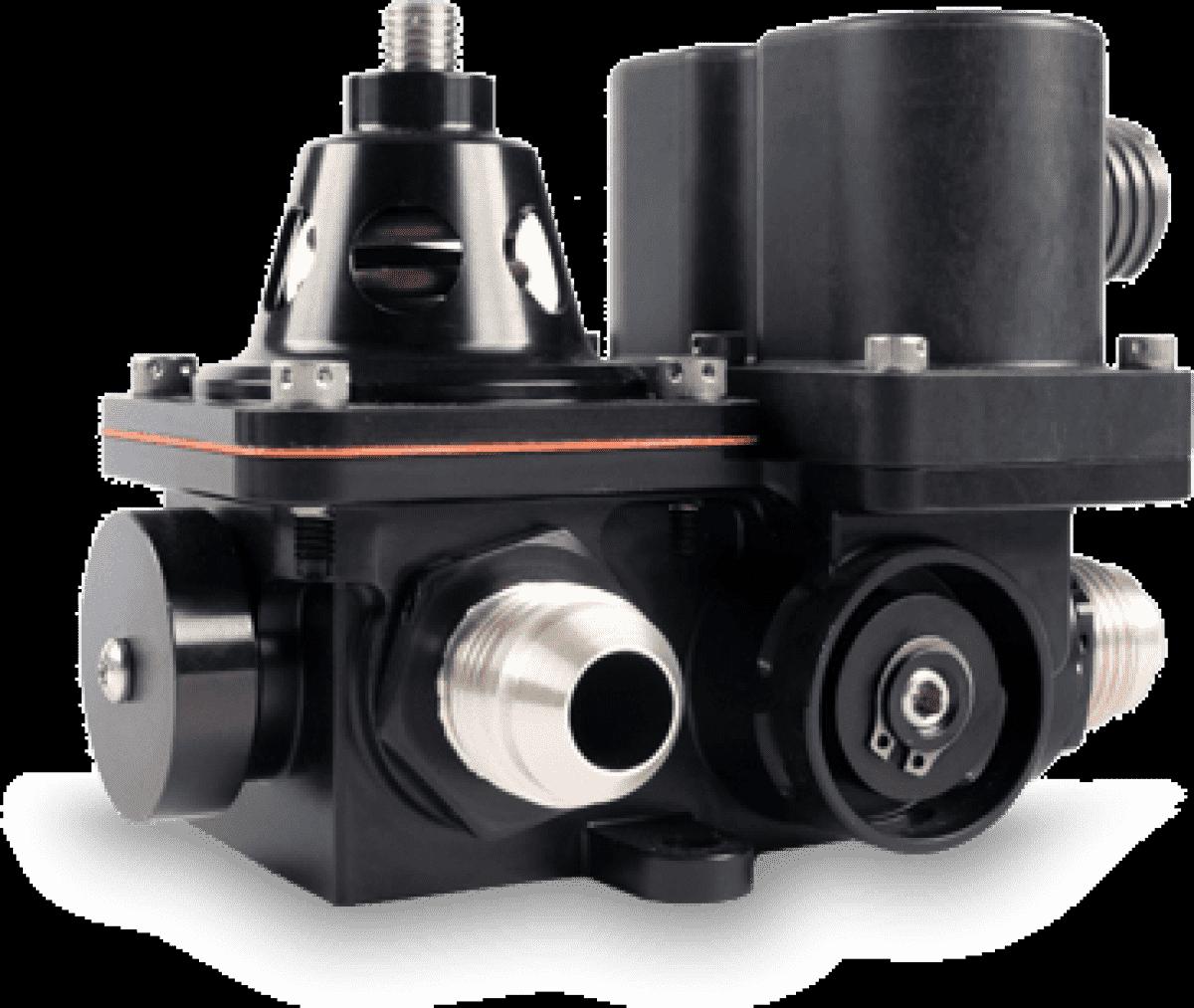

Actuators are devices that control the movement of aircraft parts. They are essential for the safe and efficient operation of aircraft. In this blog post, we will discuss how an aircraft actuator can improve the efficiency of an aircraft. We will also provide some tips on how to choose the best actuator for your aircraft.

Overview of Aerospace Linear Actuators

Aerospace linear actuators are used in aircraft for everything from flying the plane and controlling its turns to moving landing gear. These hydraulic motors use fluid power to move masses through a medium, such as air or oil.

There are two main types of aerospace linear actuators: those that use pressurized fluids (like pumps) and those that use compressed gasses (like nitrogen).

Piston presses require very high pressures to operate; while compressors can produce much lower pressures, they're more efficient when running at higher speeds. Both types of actuators work best when their speed is controlled so that the motion stays smooth across a wide range of conditions.

Types of Aerospace Linear Actuators

Aircraft actuators are essential for aircraft control and can improve the efficiency of aircraft operations. There are three main types of aerospace linear actuators: electric, pneumatic, and hydraulic. Electric actuators use electric power to move the actuator arm. Pneumatic actuators use air pressure to move the actuator arm. Hydraulic actuators use hydraulic fluid to move the actuator arm.

Applications for Aerospace Linear Actuators

How an Aircraft Actuator Can Improve the Efficiency of an Aircraft

Actuators are important components of aerospace systems and play a vital role in the proper functioning of an aircraft. They allow systems to be controlled by movements or electrical signals, allowing them to maintain their orientation or flight path. Aerospace actuators can improve the efficiency of an aircraft by altering its aerodynamic properties. For example, a flap actuator can increase the lift generated by an aircraft wing, while a rudder actuator can adjust the angle of the plane's nose in order to control its direction. Additionally, actuators can improve upon aircraft performance by modifying airflow around and through an airplane. By redirecting air flows over or near critical engine parts, for instance, actuators can prevent catastrophic failure during flights.

The Benefits of an Aircraft Actuator

The benefits of an aircraft actuator include increased efficiency, reliability, and safety. Aerospace linear actuators are used in a variety of applications throughout the aviation industry, including recreational flying and commercial aviation. The actuator is able to generate powerful forces to move objects or vehicles through the air. This allows for greater speeds and smoother movement. By increasing the efficiency of airplane movements, an aircraft actuator can improve overall performance.

The Different Types of Aircraft Actuators

Most people think of aircraft actuators as being used to control the motion of an airplane or spacecraft, but that's just one application. There are many other potential applications for aerospace linear actuator technology. In this article we will discuss some of the different types of aircraft actuators and their possible applications.

When it comes to precision, there is simply no match for an aerospace linear actuator when it comes to moving things mechanically. This type of actuator is found in a wide range of industries including medical equipment, automotive manufacturing, and agriculture. Aerospace linear actuators are even used in spaceflight because they offer the highest degree of reliability and accuracy.

The first type of aerospace linear actuator is electrical actuation systems which use electricity to move the actuator. These are limited in terms of size, but they offer high precision and reliability.

The second type of aerospace linear actuator is pneumatic actuation systems which use compressed air to move the actuator. These systems are more versatile because they can be used in a wider range of applications. However, they have lower precision and reliability than electrical actuation systems.

The third type of aircraft actuator is hydraulic actuation systems which use liquid or gas pressure to move the actuator. This system offers the highest degree of adjustability, but it also has the lowest precision and reliability.

A fourth type of aircraft actuator is screw drive systems which use screws to move the actuator arm. This system is the most versatile, but it also has the lowest precision and reliability.

The fifth type of aircraft actuator is ball screw systems which use balls to move the actuator arm. This system is the most accurate, but it also has the lowest precision and reliability.

How to Choose the Right Aircraft Actuator

Aircraft actuators are used in a variety of applications, from controlling the flight of planes and helicopters to moving parts in industrial machinery. They can be found in both commercial and military aircraft, and their efficiency is critical to the success of these vehicles.

There are several types of aerospace linear actuators, each with its own advantages and disadvantages. The most common type is the electric motor actuator, which uses an electric motor to move the armature. Electric actuators are relatively simple and easy to operate, but they can be less efficient than other types of actuators.

Another common type of aircraft actuator is the hydraulic actuator. Hydraulic actuators use pressurized fluid to move the armature, and they are much more efficient than electric actuators. They are also more complicated to operate, so they are not ideal for small aircraft.

The final type of aircraft actuator is the pneumatic actuator. Pneumatic actuators use compressed air to move the armature, and they are the most efficient type of actuator. They are also the most difficult to operate, so they are not ideal for small aircraft.

When choosing an aircraft actuator, it is important to consider the application and the size of the aircraft. The type of actuator also matters, as different types are better suited for different applications.