Selecting A 316 Stainless Steel Wire Manufacturer

- - Category: Industrial

- - 23 Sep, 2022

- - Views: 336

- Save

316 stainless steel wire can be found in the following applications:

Grade 316 stainless steel wire is an austenitic chromium-nickel steel that has a mid-range of carbon and around 3 percent molybdenum. Because Grade 316 stainless steel contains molybdenum, it is suitable for marine applications and commercial kitchen applications due to its high resistance to corrosion. It is also particularly resistant to acids and high temperatures. 316 stainless steel wire is essentially nonmagnetic. The corrosion-resistant properties of 316 make it particularly useful in the construction industry, and popular in the pharmaceuticals industry because it is so resistant to chemicals. 316 is easy to weld, and it is inert, which means it is suitable for food preparation and medical-grade applications.

Benefits of 316 Stainless Steel Wire

316 stainless steel is incredibly heat resistant, performing well in temperatures up to 800 °C. It is superior to other grades of steel in terms of resistance to rust and abrasion. It is easy to weld with TIG or MIG welding, and is nonmagnetic when annealed. This family of alloys is simple to shape with braking or rolling. It has high tensile strength and is recyclable.

Applications

316 stainless steel wire can be found in the following applications:

- Aerospace

- Automotive

- Architectural

- Chemical

- Food and beverage

- Pharmaceutical

- Medical

- Oil refineries

- Power plants

- Telecommunications

- Photography

- Textile

- Paper

- Transportation

Searching for a Supplier

The Drawing Process

When selecting a 316 stainless steel wire manufacturer, it is important to find a company that uses modern techniques and processes to produce your materials. This ensures that you receive the highest levels of precision for sizing, temper, and packaging. A company that uses wire drawing, for example, will offer excellent surface finishing, mass production capabilities, control and mastery of demanding wire gauges and dimensions, economic efficiency, and a timely turnaround.

Tempering

Tempering of stainless-steel wire involves heating the material up to a high heat, then cooling it down. This reduces the internal stress on the metal, increases corrosion resistance, and strengthens the metal. Tempering is an essential part of proper 316 stainless steel wire manufacturing.

Certification

It is essential that your 316 stainless steel manufacturer conforms to ISO 9001:2015 and is certified as doing so. This standard refers to quality management and is essentially a certification that your wire is manufactured to the highest possible quality.

Expertise

Seek out a supplier with decades of experience. There are many companies out there with a long history of providing affordable, high-quality 316 stainless steel wire. It is worth checking out their previous customers to see what their experience was like. With a long track record of satisfied customers, however, you can be more confident that the supplier will provide you with the high standard of material that you expect.

Flexibility

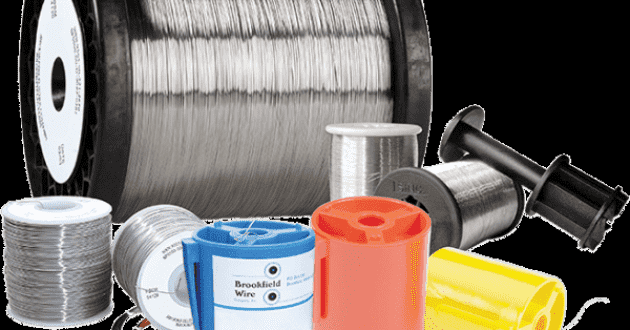

The best suppliers offer 316 stainless steel wire in many different configurations, from bulk spools to canisters, Handi-Pak coils, and bobbins. You should expect savings on bulk steel, too, as the price for material will go down based on how much you order.